The simple fact is, without proper ice machine cleaning your machine is at risk for scale, slime, and sediment. In this article, we’ll show you how to identify these contaminants and what you can do to rid yourself of them.

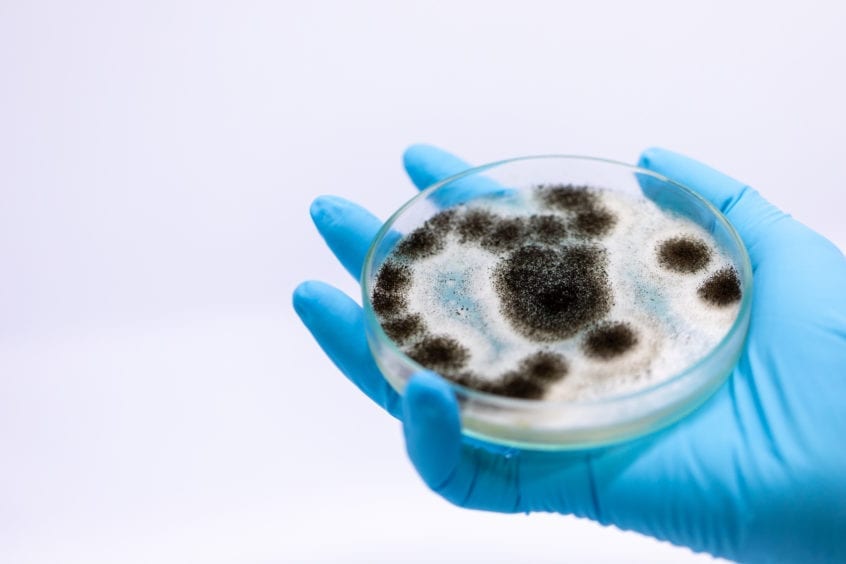

Slime and Mold

Print & Post this Cleaning Schedule!

Slime and mold form because the ice-making process is exposed to the air around you. Since your city chlorinates drinkable water, it’s rarely the source of contamination. The air, however, is filled with many contaminants, including mold spores and bacteria that can lead to a dirty ice machine.

As water flows over the ice making surface of your ice machine, these contaminants spread through the ice machine. Other airborne contaminants, like yeast, will feed the mold until it matures and begins to change color.

We have customers that have noticed visible mold in less than 21 days. For these environments, we have designed preventive ice machine cleaning, treatment, and remediation programs so these customers can enjoy clean and safe ice.

How to Clean Slime and Mold from an Ice Machine

Ice machine users can clean mold and slime from their ice machine with a few simple steps. This is not the same as a professional ice machine cleaning from a qualified technician, but our ice machine cleaning schedule helps tremendously to keep mold and slime at bay.

To clean mold and slime:

- In a spray bottle, mix a solution of 20% chlorine and 80% water

- Use the spray bottle to saturate any contaminated surfaces

- If needed, wipe the areas to remove the contaminants

- After wiping, reapply the solution

- Important: Leave the mixture to air dry

For more information, please read our article How to Clean an Ice Maker: Mold and Slime Removal.

Scale

Scale build up in dirty ice machine

Scale will form in every ice machine without regular ice machine cleaning. Calcium and magnesium – the ions that form scale – are in every water source. The concentration of these minerals, measured by hardness, determines how fast scale forms and how frequently you need to clean your machine.

While scale does NOT present a health hazard, it will affect the reliability of your machine as well as it’s lifespan. In the short-term, scale will clog valves and distribution tubes, slowing down the ice-making process or disable the machine altogether.

In the long term, scale buildup on the ice making surface (the evaporator) causes a condition called “pitting.” Pitting happens when scale adheres so firmly to the evaporator; it tears a microscopic chunk out of the evaporator when removed. That “pit” attracts more scale, which causes more damage during cleaning. This cycle continues, creating a deeper pit, which leads to an expensive evaporator replacement or new machine purchase.

The most severe scale condition we have observed was in southeast Ohio, where a brand-new ice maker was clogged by scale in 6 days.

How to Prevent and Clean Scale from an Ice Machine

There are a few treatments that can help you prevent scale buildup:

- Treating your water supply with a dedicated water softener

- Adding a phosphate filter to the ice machine

- Installing a reverse osmosis system

Cleaning scale requires using harsh chemicals and is better done by a qualified ice machine technician.

For more information, read our article How to Prevent Scale Buildup in Your Ice Machine.

Sediment

Sediment is one of the most insidious of the ice machine problems because it sneaks up on you without many observable characteristics. Every water source has suspended particles. Filtration by your city’s water treatment facility manages the particulate count leaving the treatment plant, but a network of pipes – possibly hundreds of miles long – delivers the water to your ice machine.

Some of those pipes may be old, which can flake and add particulates to the water source. Once inside the ice machine, particulates get inside the pump, valves, float switch, etc. and can gum everything up, damaging the ice machine.

How to Prevent Sediment in an Ice Machine

Dedicated filtration is the first line of defense for reducing particulates in the ice machine. You should install a standard sediment water filter for your ice maker. We use a 5-micron filter sediment filter on all our compatible ice machines.

Sediment filters should be replaced about every six months, depending on your water use, supply, and quality.

Finally, effective preventive maintenance and ice machine cleaning will remove sediment buildup so it can’t cause problems in the long run.

Identify Potential Risks Before They Start

Since so many factors can cause ice machine problems, it’s crucial to monitor the conditions that give rise to these threats. A change in menu, a change in water supply sources negotiated by your city, etc. can all have an impact on how your ice machine operates. It’s important to have a good ice machine service provider that routinely looks for the warning signs.

Here at Easy Ice, our ice machine subscription program comes with a top-of-the-line ice making machine along with cleaning, maintenance, and any repairs that might arise. We aim to earn your business every day, which is why we care about your ice supply as much as you do.

Share this Post